Build thread (DME controlled MAC, Dual HPFP, Radium FST)

- Thread starter bahn

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Thanks for the comments. Bleeding is the same as factory except you don't have a bleeder screw, so just leave the cap off during the bleeding procedure.Love the development and ingenuity, awesome work!

Just one question from my side in regards to the relocated coolant tank expansion hose. Any issues bleeding or works same as factory?

Also excited for direct MAC integration.

If there's interest in these panels I can have more made.That aluminum plate holding everything together looks bitchin! Reminds me of my days in the ChemE lab. Nice setup! Can’t wait to see logs.

Very interested in getting DME to run dual hpfp’s. Trying to achieve this on my n55 at the moment but having no luck

This is N54 DME only for now. I saw your PM about S55 pump retro, that only works on EWG F-series N55 DME.

This is N54 DME only for now. I saw your PM about S55 pump retro, that only works on EWG F-series N55 DME.

Wait what, I missed something.

Now I can ditch the Boost Box and the Split Second? All can be controlled by stock ECU (MSD81).

Frickin' sign me up!

So any way to get the dual hpfp to run on an e series n55? Secondary controller for second pump?This is N54 DME only for now. I saw your PM about S55 pump retro, that only works on EWG F-series N55 DME.

Wait what, I missed something.

Now I can ditch the Boost Box and the Split Second? All can be controlled by stock ECU (MSD81).

Frickin' sign me up!

The second pump still requires an intermediate control box, as the N54 DME does not have the ability to power it. However, the actual duty cycle sent to the board @bahn designed does come from the DME.

Moving on to the fuel system, this car has more fuel than I know what to do with to be honest. In the trunk I have a 1/8" laser cut aluminum panel that's replacing the ABS insert. Mounted to that we have a Radium Fuel Surge Tank with two walbro 450's installed. The factory lift pump remains to fill the fuel surge tank and is still volume controlled by the DME with the factory EKP. The primary walbro 450 pump is volume controlled by the DME as well with another EKP. The second walbro 450 pump is relay controlled and actuated by the DME.

First I've seen anyone running multiple EKP modules, how does that work? Definitely the sickest fuel setup I've seen on an N54, thanks for sharing!

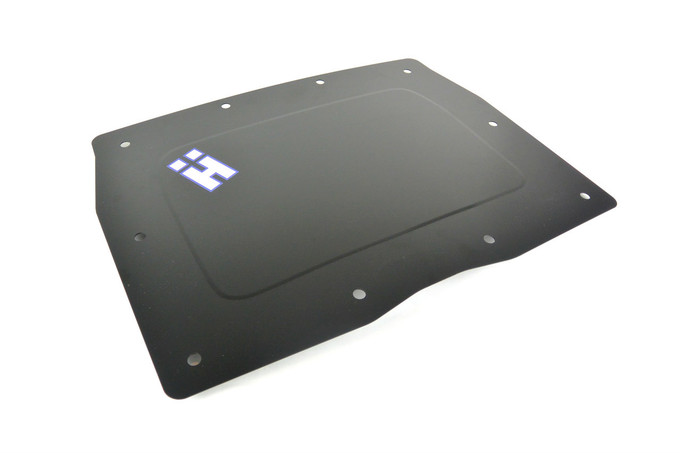

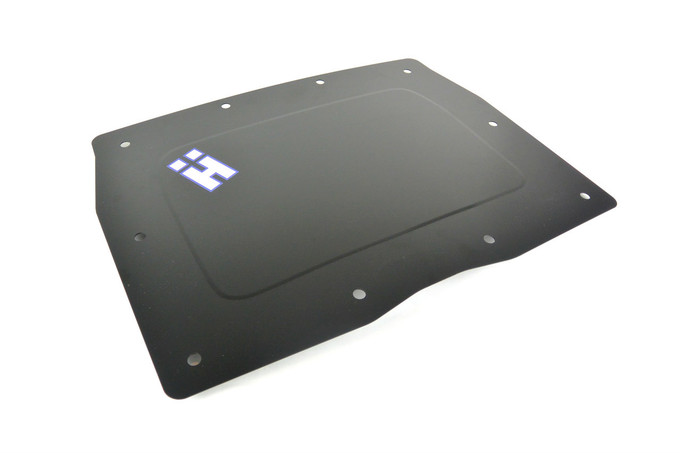

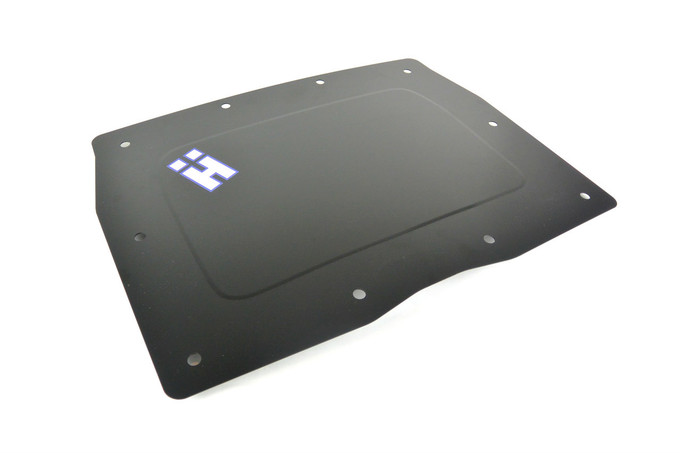

For anyone interested, I cam across a delete panel:

www.hardmotorsport.com

www.hardmotorsport.com

HARD Motorsport - BMW E9X Trunk Floor Filler Panel

Prepping your car for the track? Stripping the excess weight and plastics out of the modern BMW will leave a gaping hole in your trunk. The HARD Motorsport Trunk Filler Panel is the only drop-in solution available for your E90, E92 M and non-M chassis.

Yeah, saw that when I was looking at making my own. Didn't like how thin it was so I went with 1/8". I can have more made if there's interest.For anyone interested, I cam across a delete panel:

HARD Motorsport - BMW E9X Trunk Floor Filler Panel

Prepping your car for the track? Stripping the excess weight and plastics out of the modern BMW will leave a gaping hole in your trunk. The HARD Motorsport Trunk Filler Panel is the only drop-in solution available for your E90, E92 M and non-M chassis.www.hardmotorsport.com

Sick setup Bahn! Subbed and super keen for more deets.. Any chance you can give us a rundown on how you've integrated dual EKP modules?

screaminfast

Sergeant

Not much to it really but I'm still testing this setup so I don't want to write a how-to guide until it's been properly vetted. If you have an urgent need send me a PM and we can discuss.Sick setup Bahn! Subbed and super keen for more deets.. Any chance you can give us a rundown on how you've integrated dual EKP modules?

Replied to your PM, grounding the coils to 3 valve cover bolts. Injector's have their own grounds going back to the DME on connector X60006 pins 7-12.Did you eliminate the grounding posts and ground the injector wires somewhere else?

Been awhile since an update so here we go.

* DME controlled MAC solenoid (without boost box) is working well. Been working with @jyamona adding support for MSD81 DME's as there's some coding changes that make the MSD80 approach not feasible. We both believe we're close on that front and it's working on my MSD81 bench DME, just need to do some in car testing and captures with the scope before Jake moves forward for a beta release.

* Dyno'd the car (Dynojet) on 20 psi and made 570whp @ 6300 and 523ftlbs at 4800 but experienced misfires around 6000 rpm (thought to be spark blow out, plugs were gapped to .022). Very conservative timing and no vanos changes yet, just a baseline to improve on. In response I've installed PR coils and left the gap at .022, planning to go back on the dyno shortly to test changes. It's cold here in Iowa now so bringing it on the streets is pointless.

Please forgive the dust everywhere, explanation below. Not very happy with how the wiring looks here and how close coil #1 & #2 are to the turbo blanket. @m18performance has a solution for this that is arriving in the mail today for testing . The stock PR N54 bracket was hitting the downpipe so I took a flap disc to it for clearance. Also a super sweet new oil cap from @m18performance (I have a billet addiction problem and he's a bad influence).

. The stock PR N54 bracket was hitting the downpipe so I took a flap disc to it for clearance. Also a super sweet new oil cap from @m18performance (I have a billet addiction problem and he's a bad influence).

* Rushed to the drag strip for the last test and tune of the season and sent her a little too hard in second gear (wasn't using boost by gear). Exploded the rear end mid-way through second once the load was sufficient to hit ~18 psi. Broke the spider pin, the diff housing itself, turned the spider gears into sand and of course removed some teeth from the pinion and ring gear. Ended up replacing it on my friends lift on his farm while he was harvesting which is why everything is covered in dust. While the rear-end was out I installed some Whiteline diff bushings and a new rear end (these are awesome).

* I've been working in assembly on these DME's for a year or so now but mainly from the point of understanding of logic, finding addresses of undefined tables and etc. Recently I've made some code changes on my bench MSD81 to bypass EWS/CAS for bench use only (no I won't help you do this) and used my waveform generator to feed it cam/crank signals so it thinks it's running an engine. This has been extremely helpful for testing logic changes and verifying outputs with the scope. DME LPFP triggering isn't anything "new" as @jyamona has done it already but it's not out in the wild for use in the MHD app, does require assembly code changes and he's a busy guy. So I went ahead and gave it a shot by repurposing the exhaust flap sub-routine, removing logic checks for speed, cat heating and etc. I modified the sub-routine to use a 2 byte single value load target instead of the 3D table of RPM/Gear with a Z of Torque Request %. The load target is then compared every 100ms against actual load instead of requested load to avoid false triggering due to throttle blips/stabs. The code works on my bench MSD80 & MSD81 and preliminary testing on my car was also a success. While this is a very small change compared to what @jyamona has been doing recently I'm still pretty proud of it and can't thank @jyamona enough for his assistance and mentoring. After full testing is confirmed I plan on tackling some additional low hanging fruit.

Thanks for following my build/adventures so far, as always let me know if you have any questions.

* DME controlled MAC solenoid (without boost box) is working well. Been working with @jyamona adding support for MSD81 DME's as there's some coding changes that make the MSD80 approach not feasible. We both believe we're close on that front and it's working on my MSD81 bench DME, just need to do some in car testing and captures with the scope before Jake moves forward for a beta release.

* Dyno'd the car (Dynojet) on 20 psi and made 570whp @ 6300 and 523ftlbs at 4800 but experienced misfires around 6000 rpm (thought to be spark blow out, plugs were gapped to .022). Very conservative timing and no vanos changes yet, just a baseline to improve on. In response I've installed PR coils and left the gap at .022, planning to go back on the dyno shortly to test changes. It's cold here in Iowa now so bringing it on the streets is pointless.

Please forgive the dust everywhere, explanation below. Not very happy with how the wiring looks here and how close coil #1 & #2 are to the turbo blanket. @m18performance has a solution for this that is arriving in the mail today for testing

* Rushed to the drag strip for the last test and tune of the season and sent her a little too hard in second gear (wasn't using boost by gear). Exploded the rear end mid-way through second once the load was sufficient to hit ~18 psi. Broke the spider pin, the diff housing itself, turned the spider gears into sand and of course removed some teeth from the pinion and ring gear. Ended up replacing it on my friends lift on his farm while he was harvesting which is why everything is covered in dust. While the rear-end was out I installed some Whiteline diff bushings and a new rear end (these are awesome).

* I've been working in assembly on these DME's for a year or so now but mainly from the point of understanding of logic, finding addresses of undefined tables and etc. Recently I've made some code changes on my bench MSD81 to bypass EWS/CAS for bench use only (no I won't help you do this) and used my waveform generator to feed it cam/crank signals so it thinks it's running an engine. This has been extremely helpful for testing logic changes and verifying outputs with the scope. DME LPFP triggering isn't anything "new" as @jyamona has done it already but it's not out in the wild for use in the MHD app, does require assembly code changes and he's a busy guy. So I went ahead and gave it a shot by repurposing the exhaust flap sub-routine, removing logic checks for speed, cat heating and etc. I modified the sub-routine to use a 2 byte single value load target instead of the 3D table of RPM/Gear with a Z of Torque Request %. The load target is then compared every 100ms against actual load instead of requested load to avoid false triggering due to throttle blips/stabs. The code works on my bench MSD80 & MSD81 and preliminary testing on my car was also a success. While this is a very small change compared to what @jyamona has been doing recently I'm still pretty proud of it and can't thank @jyamona enough for his assistance and mentoring. After full testing is confirmed I plan on tackling some additional low hanging fruit.

Thanks for following my build/adventures so far, as always let me know if you have any questions.